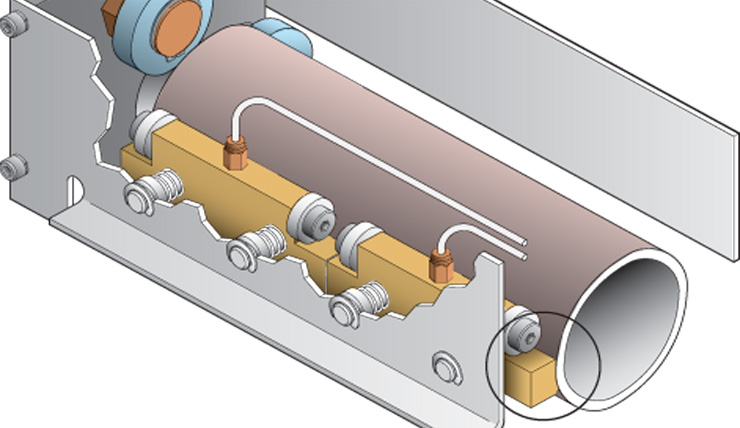

Dispensing heads are held against the rolls and lubricant is dispensed upon command. The LSP electronic controller is programmed to dispense the correct amount of lubricant for each cycle of the press. A floating chassis allows the rolls to float with the coil stock insuring that the rolls are always in contact with the material. Lubricant to the FloaterCoater is controlled with either manual on off valves or with the LSP Controller itself for precise lubricant usage.

LSP - Airless Spray System - Floated Coater

HOW THE FLOATERCOATER WORKS.

Dispensing Heads

Heads are individually selected by the On/Off Valve and are spring loaded against the Lubricating Rollers. Faces conform to the Lubricating Roller’s curvature to ensure an even spread of lubricant onto the roll.

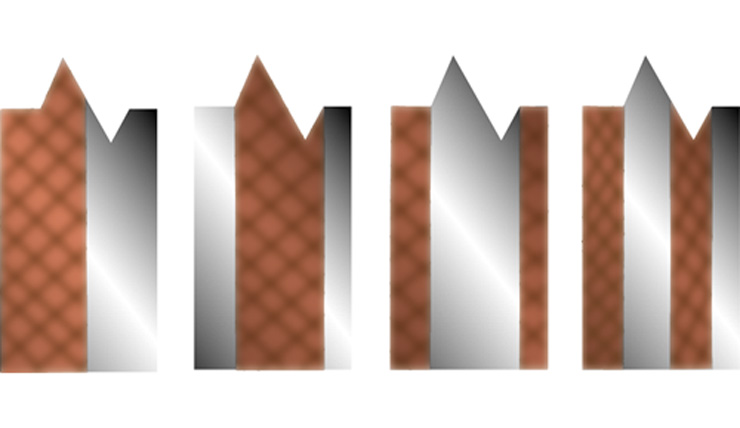

Apply Lubricant Only Where Needed

Each Dispensing Head is controlled with an ON/OFF Valve. Closing a valve prevents lubricant from coating a specific area of the coil stock.

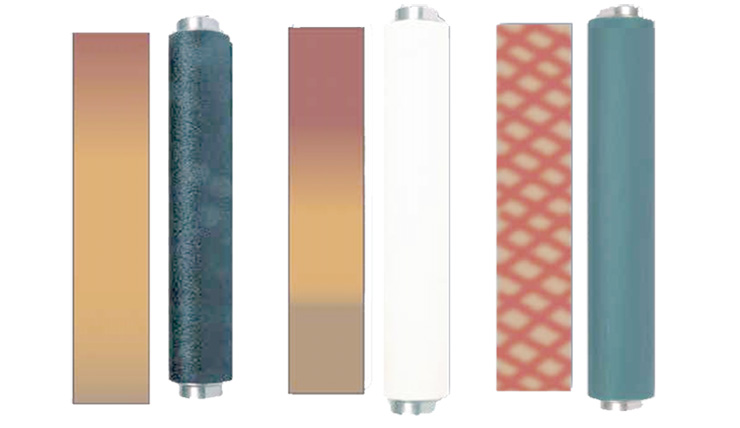

Roll Types to Cover a Range of Applications

PresSpray Module is mounted on a Reservoir. Preassembled so that just the Nozzles and the Actuator have to be installed.

Polyurethane with a Smooth Finish (left) applies a very light coating. Felt Rolls (center) give more versatility in lubricant thickness. Polyurethane with a Textured Finish (right) provide a heavier coating.

Tosyo Equipments Sdn Bhd | Airless Spray System – Floated Coater